Brake pads are an essential component of every vehicle's braking system, responsible for providing the necessary friction to stop the vehicle. These small but critical parts are made using a combination of different materials, each chosen for its specific properties.

The manufacturing process of brake pads starts with the selection of the raw materials. The most common materials used in brake pads include metallic fibers, ceramic fibers, organic fibers, and rubber. Each material has unique characteristics that affect the performance of the brake pad.

Once the raw materials are selected, they are mixed together with a binder, which holds the materials together during the manufacturing process. The binder can be made of various materials, but phenolic resin is the most commonly used binder.

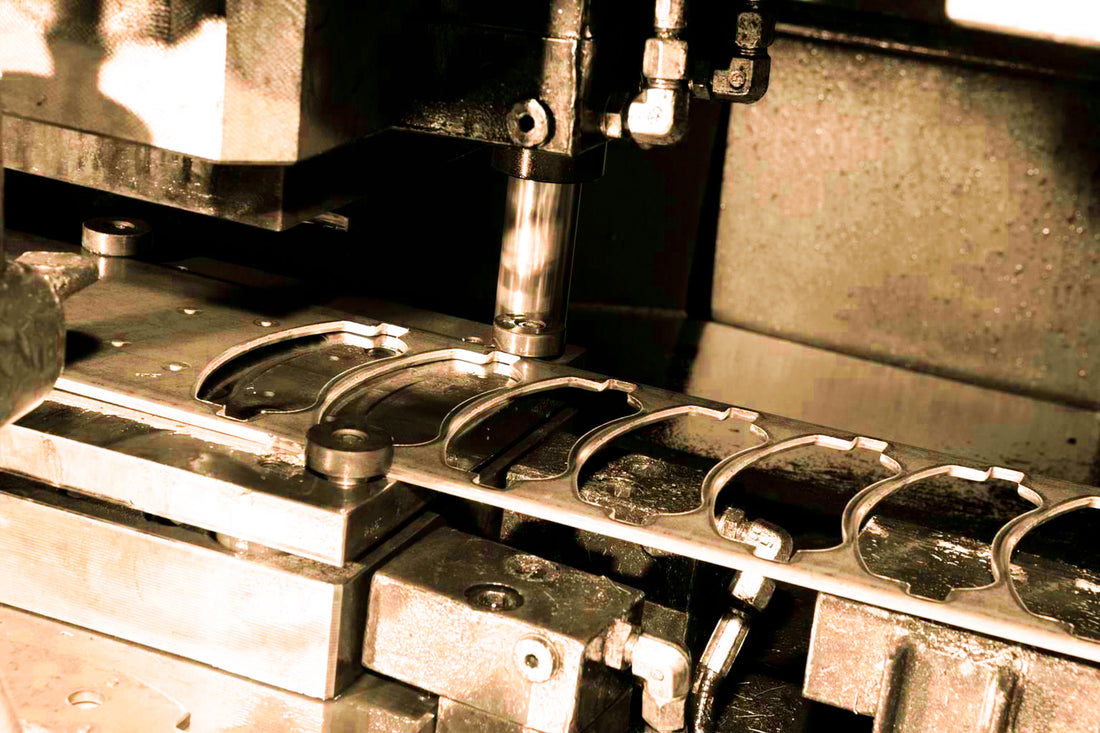

After the materials and binder are mixed together, they are then heated and compressed into a mold under high pressure. The mold shapes the brake pad into the desired size and shape, and the high pressure ensures that the materials are tightly packed together.

The brake pad is then cured in an oven at high temperatures, which activates the binder and hardens the material. After curing, the brake pad is sanded and trimmed to remove any excess material and to ensure that the brake pad meets the required specifications.

Finally, the brake pad undergoes a series of quality control tests to ensure that it meets the required safety standards. The tests include checking the thickness and uniformity of the pad, as well as its resistance to heat and wear.

In summary, the manufacturing process of brake pads involves selecting the raw materials, mixing them with a binder, compressing them into a mold, curing the pad, sanding and trimming, and quality control testing. This intricate process ensures that brake pads are made to high-quality standards, providing the necessary friction to stop a vehicle and keeping drivers and passengers safe on the road.